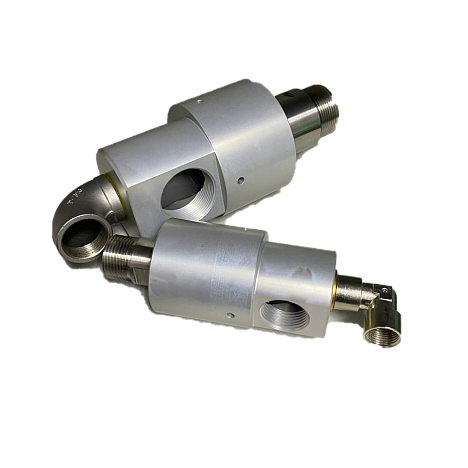

HS-RPS

Description:

The RPS seal combines two different types (rod and piston) at the same time. Due to two symmetrical edges, the cuff is used to seal both the stem and the piston in single-acting and double-acting cylinders. A profile with identical edges and a deep groove provides low friction and linear motion even at low pressure.

Technical specifications:

Pressure: < 400 bar at +60В°C.

Speed: < 0,5 m/s.

Temperature: from -35В°C to +100В°C with a peak value of +110В°C.

Operating environment: mineral hydraulic oil (see Table 1 on page 1.2.4).

Material:

Name: polyurethane (PU).

Addition: wear resistant polyurethane, resistant to hydrolysis.

Properties: has a high modulus of elasticity, low residual deformation and high abrasion resistance.

Hardness: Shore 93 В± 2.

Material code: CO.

Installation:

High elasticity modulus of polyurethane facilitates installation.

It is necessary to observe the permissible value of the surface roughness (grinding of the landing groove, for all its dimensions).

- Description

Description:

The RPS seal combines two different types (rod and piston) at the same time. Due to two symmetrical edges, the cuff is used to seal both the stem and the piston in single-acting and double-acting cylinders. A profile with identical edges and a deep groove provides low friction and linear motion even at low pressure.

Technical specifications:

Pressure: < 400 bar at +60В°C.

Speed: < 0,5 m/s.

Temperature: from -35В°C to +100В°C with a peak value of +110В°C.

Operating environment: mineral hydraulic oil (see Table 1 on page 1.2.4).

Material:

Name: polyurethane (PU).

Addition: wear resistant polyurethane, resistant to hydrolysis.

Properties: has a high modulus of elasticity, low residual deformation and high abrasion resistance.

Hardness: Shore 93 В± 2.

Material code: CO.

Installation:

High elasticity modulus of polyurethane facilitates installation.

It is necessary to observe the permissible value of the surface roughness (grinding of the landing groove, for all its dimensions).

en

en

Русский [ru]

Русский [ru]