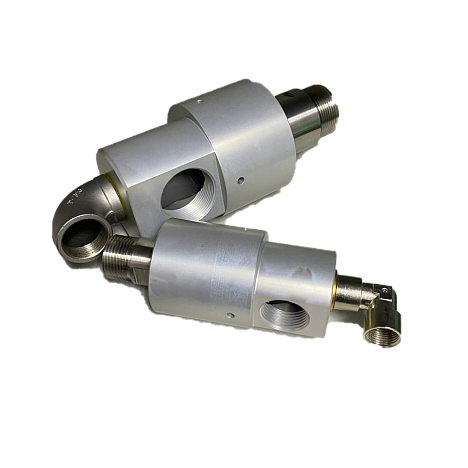

HS-RSO

Description:

The RSO rod seal is designed to replace PTFE seals or joint applications with them, since the dimensions of the seats are exactly the same. Inside the circular groove an o-ring is installed, which activates the static and dynamic edges even at zero pressure.

Due to the low coefficient of friction, this type of seal works excellently at low speeds and pressures.

Technical specifications:

Pressure: < 250 bar at +60В°C.

Speed: < 0,5 m/s.

Temperature: from -35В°C to +100В°C with a peak value of +110В°C.

Operating environment: mineral and hydraulic oil (see Table 1 on page 1.2.4).

Material:

Name: polyurethane (PU).

Addition: wear resistant polyurethane, resistant to hydrolysis.

Properties: has a high modulus of elasticity, low residual deformation and high abrasion resistance.

Hardness: Shore 93 В± 2.

Material code: CN.

Installation:

It is necessary to observe the permissible value of the surface roughness (grinding of the landing groove, for all its dimensions). For more information, see the Installation Instructions on page 1.2.14.

- Description

Description:

The RSO rod seal is designed to replace PTFE seals or joint applications with them, since the dimensions of the seats are exactly the same. Inside the circular groove an o-ring is installed, which activates the static and dynamic edges even at zero pressure.

Due to the low coefficient of friction, this type of seal works excellently at low speeds and pressures.

Technical specifications:

Pressure: < 250 bar at +60В°C.

Speed: < 0,5 m/s.

Temperature: from -35В°C to +100В°C with a peak value of +110В°C.

Operating environment: mineral and hydraulic oil (see Table 1 on page 1.2.4).

Material:

Name: polyurethane (PU).

Addition: wear resistant polyurethane, resistant to hydrolysis.

Properties: has a high modulus of elasticity, low residual deformation and high abrasion resistance.

Hardness: Shore 93 В± 2.

Material code: CN.

Installation:

It is necessary to observe the permissible value of the surface roughness (grinding of the landing groove, for all its dimensions). For more information, see the Installation Instructions on page 1.2.14.

en

en

Русский [ru]

Русский [ru]